Porometry

Porometry is a technique also utilised for the determination of pore-size distribution of a porous material. Porometry is a non-destructive technique, in the sense that the same sample can be repeatedly measured. The method utilises a liquid expulsion technique, where a sample that has been fully wetted and saturated by a liquid is expelled by increasing the gas pressure above the menisci. The wetting liquid is specifically chosen to have the properties of low surface tension, low vapour pressure and low reactivity. To ensure complete saturation by wetting, some samples may require wetting under vacuum (Calvo et al., 1995). The sample has to be saturated, not just wetted, if required the sample is saturated using the wetting fluid under vacuum.

Wetting alone can mean that just the inner surface of the pores is wetted by a film of liquid. It is necessary to establish a meniscus bridging the whole pore diameter if a measure of pore size is to be obtained. A continually increasing gas pressure is applied across one external sample face. The gas phase progressively replaces the wetting fluid in ever finer pores as the gas pressure is increased. Eventually, the liquid is expelled as the gas phase pressure exceeds the capillary wetting pressure. Throughout the analysis, surface tension of the wetting fluid acts to retain the wetting phase within the pore structure. Therefore, when removing the wetting fluid from the pore structure, by means of the gas overpressure, the surface tension needs to be overcome. The pressure required is, therefore, equivalent to the capillary pressure (Amey et al., 2008).

The limits of validity for porometry have not been determined in the literature. The manual for the instrument states the pore size range for the instrument is 0.07 – 300 µm. Porometry is used within the filtration industry as a quality control tool to ensure consistency of filter media between production batches, and to characterise filters.

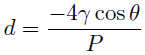

The sizes of pore features are related to flow rate versus gas pressure by the Laplace-Washburn equation. The non-wetting fluid used by porometry is air or nitrogen.

The Laplace-Washburn parameters are changed for porometry when compared with mercury porosimetry, in that contact angle of the wetting fluid θ is 0°, thus changing the negative sign into a positive sign in respect to the cosine function, and interfacial tension γLV is 0.016 N m-1. The instrument is connected to a gas supply with a typical maximum pressure of 13 bar and a minimum flow rate of 100 dm3 (litres) per minute.

The non-wetting fluid used to displace the wetting fluid is typically air or nitrogen and the properties of the interface between the wetting and non-wetting fluid depend on the wetting fluid and the non-wetting fluid. For more information about the wetting non -wetting fluid interface please contact your porometer instrumentation supplier.