Thermal heating effects

If the mercury intrusion occurs too fast, the mercury heats up because the applied pressure is converted to kinetic and then thermal energy as the mercury is forced through very small voids. So the mercury expands. The porosimeter does not know that - it assumes that the temperature of the mercury in the micro- , meso- and nano- pores is at the ambient (laboratory) temperature. As the mercury expands, then less of it intrudes. So the intrusion curve shows less maximum intrusion at highest pressure than is correct, and the intrusion curve towards the maximum pressure limit shows less intrusion than it should do. As the slope of the intrusion curve at highest pressures is usually low anyway, then the effect does not show up when the intrusion curve is analysed by the traditional, but invalid, first derivative (slope) method. So people do not usually worry about it.

Once the pressure begins to be reduce after the maximum pressure has been reached, the mercury cools. Cooler mercury causes its volume to contract, so more of it can intrude. So we observe increased intrusion as the pressure is decreased. That is impossible for PoreXpert to model. The thermal problem is always observed on the extrusion curve, not the intrusion curve. However, a bulge in the extrusion curve shows that both the intrusion and extrusion curves are invalid. An example is shown below, which is a screen shot from the free porosimetry preprocessor PoreXY. To avoid such errors, it is essential to follow mercury porosimetry best practice, specifically in this case by carrying out the experiment more slowly.

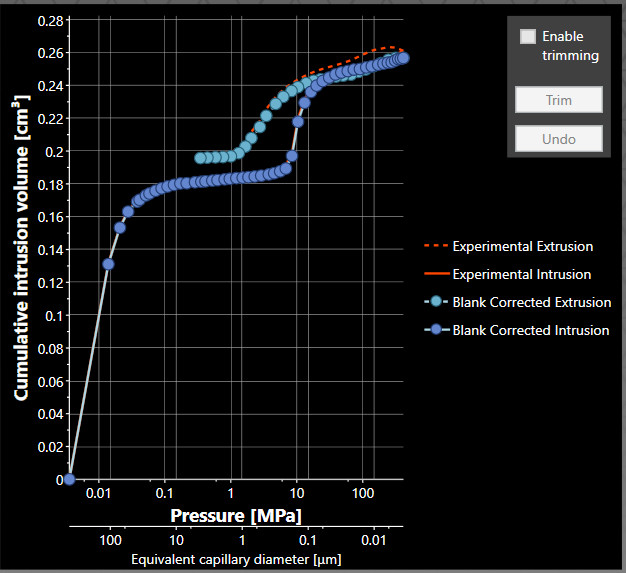

A bulge in the intrusion curve and/or the extrusion curve can be caused by an invalid blank (empty) sample holder run used as a correction - as shown in the just-visible experimental extrusion curve in the screenshot below.

For the correct protocol applied to a compressible sample, ideally both the intrusion and extrusion curve should slope upwards towards the maximum pressure, and lie on top of each other for a significant range at highest pressures, as shown by the blank corrected curves in the same screenshot.

Such effects can be corrected out of the experimental results using PoreXY, which also gives an estimation of the solid phase compressibility. After the correction, the intrusion curve can be used to generate a valid, uncompressed void network for modelling with PoreXpert, assuming that the pore level properties that are of interest are those at ambient or moderate pressures.

Extrusion curve discontinuity

Some porosimeter software purports to cure the thermal heating problem described above by chopping off the bulge of the extrusion curve, as if chopping off the top of a boiled egg before eating it. This clearly does not solve the thermal heating problem, since the intrusion curve, which is used for modelling, is still invalid. Therefore such experimental measurements should not be used for modelling, but should be properly avoided by the protocols described in a PoreXpert Help section.